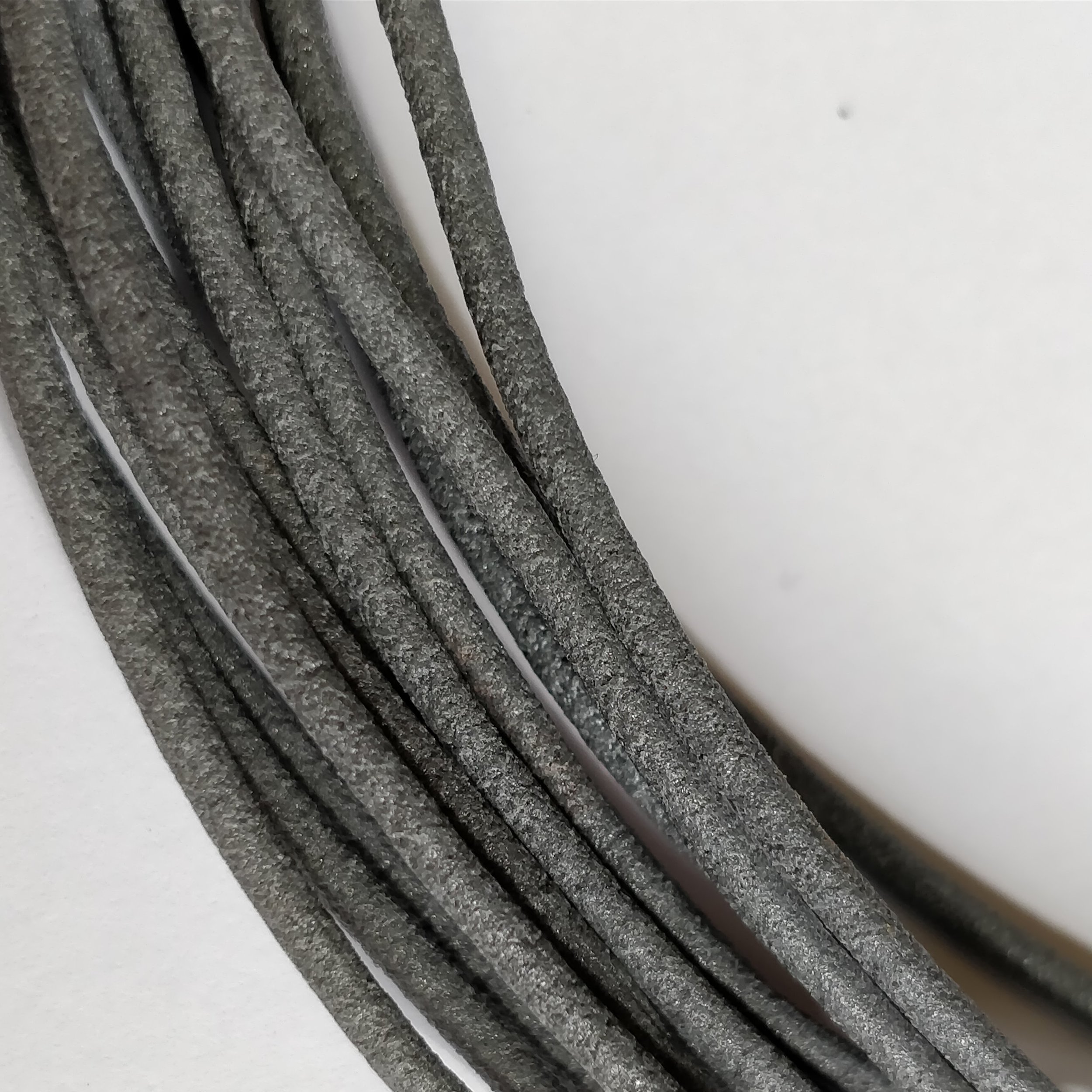

Metal Infused Filament

The Spooler

The fully assembled filament spooler

For my fourth year design project my group decided to build a metal infused filament extruder proof of concept. The purpose of this project is to provide small businesses and hobbyists a low cost method of producing metal powder infused filament. It is estimated that this extruder will cut the cost of metal infused filament by 80%. Metal infused filaments provide a shiny metal sheen and magnetic properties which traditional plastic filaments do not have.

My contributions for this project were programming the electronics, designing and manufacturing the spooling system, and testing the extruder and spooling system settings to produce filament that was up to specifications. More specifically, I used an Arduino to control the motor speed and direction for optimal filament spooling. The purpose of the spooling system is to capture the outflowing metal infused filament and wind it into a neat spool. The filament should had a diameter of 1.75mm +/- 0.1mm.

The spooler was laser cut from a 5.5mm sheet of MDF and fastened together using bolts. Both motors are controlled with an L29N dual H bridge board which allows for both directional and speed control.

Fit check of the laser cut components of the spooler

A top view of the spooler with the motor mounted

The Filament Production Process

The production process of the metal infused filament took some time to establish. At first, we had issues mixing the fine iron powder with the large PLA pellets. The iron powder fell to the bottom which resulted in filament with unevenly distributed iron powder.

Eventually, we discovered that encasing the iron powder in wax would allow us to feed in a homogeneous mixture of PLA and iron.

The full production process can be seen below.

1. Iron cake - iron powder encased with paraffin wax

2. Iron cake crushed into pellets

3. Iron cake pellets mixed with PLA pellets

4. The mixture fed through a filament extruder

5. The metal infused filament

6. The first print made using the metal infused filament